Unveiling Complexities in Supply Chain Transparency: A Persistent Puzzle!

In today's fast-paced world, it's a given that transparency and visibility are essential for robust supply chains, even the most complex ones. With the Fourth Industrial Revolution (4IR) and Industry 4.0 promising limitless transparency, you'd think that even the biggest companies would be all over it. But you'd be wrong.

I've seen it firsthand, working with big names in Consumer Packaged Goods (CPG), Automotive, and Defense Contracting. Despite their size and resources, many of them are miles away from achieving real-time visibility in their supply chains. Instead, they rely on Excel for order tracking and planning - yikes! Even their ERP systems seem to miss the mark, failing to deliver the clarity they so desperately crave.

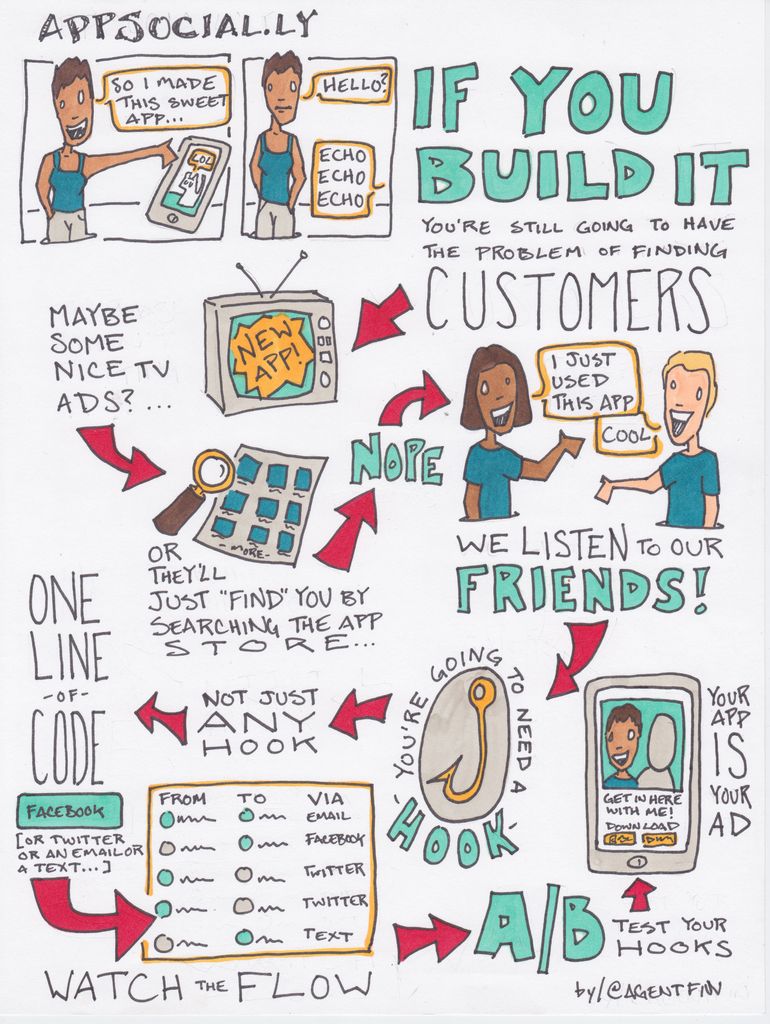

So, what's the solution? Well, buckle up, because it's not as glamorous as flashy tech solutions might promise.

Let's start at the beginning - material acquisition. That's where the limitations in supply chain visibility seem to start. Buyers and expeditors often place purchase orders with suppliers, checking the box as if it's all sorted. The order is in, so the material will arrive on time because... mistakes never happen, right?

But if we apply the 80/20 Principle, we know that this thinking is faulty. The placement of the PO is only 20% of the equation when it comes to material receipt. When we factor in ABC classification for material purchases and consider long-lead, high-value items, the equation becomes even more lopsided.

Take a look at this simple illustration:

"A" Item Example - BOM complexity, long lead time

PO Placement ➜ Supplier Receipt and acknowledgement ➜ Supplier Procurement of 800 unique parts from 50 other suppliers ➜ Material Receipt and build ➜ Shipment to customer

"C" Item Example - Distributor stock, low complexity, short lead time

PO Placement ➜ Supplier Receipt and acknowledgement ➜ Supplier pulls from stock ➜ Shipment to customer

You can see the long arrows in the diagram are where the cracks appear - opportunities for error lurk at every step. Every day that passes between nodes in the supply chain where an operation is missed, forgotten, or delayed is a delay in the supply chain.

Let's put it into real-life terms. I've seen more than a few instances where a buyer places a PO, only to find that:

- The supplier never acknowledged receipt of the order (worst-case scenario).

- The due date has slipped, and there was no communication about it.

Both scenarios could have potentially been mitigated if the buyer or expeditor had reached out to the supplier on a regular basis for status updates. But here's the catch - weekly, if not daily, phone calls or emails to order takers? Is that really the best we can do in 2021?

In a perfect world, order status would be visible in real-time through online portals and EDI communication channels. Shouldn't every part have RFID for real-time tracking and communication?

However, not everyone can afford such expensive supply chain solutions. Smaller organizations with limited product lines and simpler supply networks will likely continue to rely on old-school methods. But for large automotive manufacturers and mission-critical defense contractors, investing in a platform that eliminates the possibility of a missed shipment seems like a no-brainer.

According to the 2020 Supply Chain Visibility Report, only 60% of manufacturers and retailers claim to have end-to-end supply chain visibility[4]. This begs the question - why in a world where technology offers us more opportunity than ever to have clear sight through the entire chain, are we still lacking visibility?

The answer seems to lie in collaboration - or lack thereof. The report goes on to state that a lack of trust between organizations and a fear of sharing proprietary information are main reasons for this degradation in collaboration[4]. In other words, collaboration is the missing link.

Ramping up human interaction, as counterintuitive as it may seem in our tech-driven world, may well be the solution to this dilemma. This news is promising, especially in a world where people are worried about their jobs being replaced by robots and AI.

But is improved collaboration the end-all-be-all? Economist Thomas Sowell puts it best: "There are no solutions, there are only tradeoffs; and you try to get the best tradeoff you can get, that's all you can hope for."

Solutions aren't always as clear-cut as we'd like them to be. Sometimes we must accept certain risks to avoid others. The situation is no different when it comes to increasing supply chain visibility.

So, what do we do now? Simple - make those calls, blacklist problematic suppliers, invest in real-time tracking, and collaborate, collaborate, collaborate. It's time to embrace the old-school methods while we patiently await the tech solutions that promise to make our lives easier.

article and permission to publish here provided by Adam Miglio. Originally written for our platform and published on August 26, 2021.

Share this:

- Click to share on LinkedIn (Opens in new window)LinkedIn

- Click to share on X (Opens in new window)X

- Click to share on Facebook (Opens in new window)Facebook

Like this:

Related

Why Real-Time Supply Chain Visibility is No Longer Optional!https://our website/supply-chain-visibility-has-never-been-more-important/

Top 7 NFT Use Cases for Supply Chain Management!https://our website/characteristics-of-a-perfect-marketplace-for-nfts/

Creating Compartmentalized Supply Chains to Enhance Agility and Control!https://our website/the-agile-supply-chain-why-agility-is-trumping-lean/

Sources:

- Deloitte. (n.d.). Supply chain control tower – Bringing data to life. Retrieved from https://www2.deloitte.com/us/en/insights/topics/supply-chain/supply-chain-control-tower.htmland#related-resources

- IntegrityNext. (n.d.). Multi-tier visibility. Retrieved from https://integritynext.com/knowledge-center/supplier-risk-and-resiliency/risk-assessment/multi-tier-visibility-what-it-is-and-why-it-shouldnt-be-overlooked/

- IBM. (n.d.). Gaining real-time supply chain visibility in a digital world. Retrieved from https://www.ibm.com/services/supply-chain/supply-chain-visibility

- Sensor Tower. (2020). The 2020 supply chain visibility report. Retrieved from https://www.sensortower.com/supply-chain-visibility/

- To enhance supply chain management for global businesses, there's a pressing need for real-time visibility and improved demand planning, as the traditional Excel-based order tracking methods often fail to meet modern complexities.

- In the 4IR era, procurement and supply chain management in various industries, such as CPG, Automotive, and Defense Contracting, can harness technology to bridge the gap in supply chain visibility, moving beyond the limitations of human erroneous judgments and delays.

- An essential step toward improving supply chain visibility is ensuring accurate and timely material acquisition, a process that demands diligence and regular communication with suppliers for transparent orders and updates, rather than relying solely on the placement of purchase orders.

- Despite advancements in technology, collaboration and trust remain the weakest links in global supply chains, with some businesses still hesitant to share proprietary information, thus affecting end-to-end supply chain visibility for many manufacturers and retailers.