Disruptions in Shipping Patterns Due to Tariffs in 2025 Freight Industry Analysis

In the first half of 2025, tariffs imposed by the United States caused significant disruptions in shipping patterns and international trade. These tariffs led to unpredictable freight activity, shipment consolidations, and shifts in global trade flows.

Key effects of these tariffs include disrupted shipping patterns and increased volatility, inventory and logistics impacts, tariff escalations and trade tensions, sectoral impact and trade route adjustments, shipping industry responses, future demand uncertainty, and partial short-term relief for some partners.

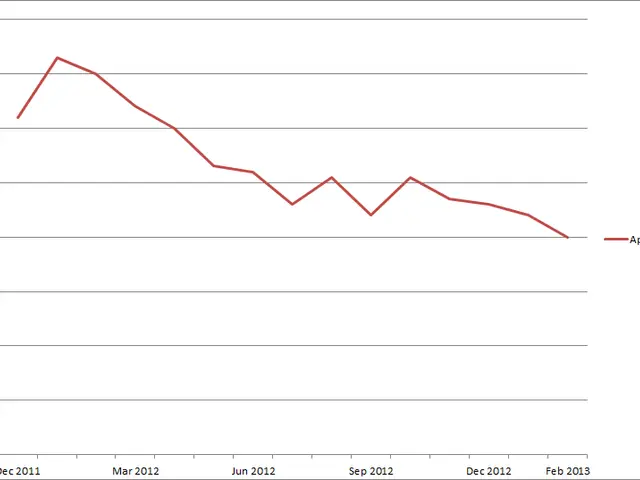

Disrupted Shipping Patterns and Increased Volatility

Tariffs led businesses to consolidate shipments to offset cost increases, causing fewer but larger shipments. This resulted in a slowdown in import orders but spikes in shipping volume as importers rushed to ship goods before new tariff enforcement deadlines, such as in March and June 2025. Order volatility rose by over 60%, reflecting market uncertainty.

Inventory and Logistics Impacts

Average on-hand inventory increased by 4% year-over-year, as firms stockpiled goods to mitigate tariff risks. However, this unpredictability caused traffic congestion at ports, scheduling irregularities, longer waiting times for cargo transfer, and general operational disruptions in global logistics chains.

Tariff Escalations and Trade Tensions

The U.S. raised tariffs sharply on imports from China and India, with Chinese tariffs peaking at 145% on some goods in April 2025, and a corresponding retaliatory tariff increase by China on U.S. goods. Additional surcharges targeted Chinese-built vessels calling at U.S. ports to bolster U.S. shipbuilding.

Sectoral Impact and Trade Route Adjustments

Sectors like automotive felt strain from steel and aluminum tariffs, with higher input costs and supply chain challenges prompting manufacturers to consider relocating production to other regions like Southeast Asia and Eastern Europe. Chinese manufacturers redirected former U.S.-bound exports, especially vehicles, toward Europe, affecting EU markets with competitively priced Chinese products.

Shipping Industry Responses

Logistics companies reduced fleets, moved equipment strategically, and adjusted operations to maintain efficiency amid tariff-induced volatility. Despite these adaptations, shipment delays and capacity congestion became common, affecting service reliability.

Future Demand Uncertainty

While stockpiling delayed consumer price impacts, a potential demand decline could emerge once pre-tariff inventories rebuild. This may lower freight rates on certain routes and advantage more profitable lanes, introducing further market volatility.

Partial Short-Term Relief for Some Partners

Trade with Canada and Mexico remained more stable through negotiated grace periods extending tariff exemptions and duty-free statuses temporarily, but these terms are subject to deadlines later in 2025.

Technological Solutions

Data from the IndexBox platform indicated a 63.7% rise in monthly order volatility, signaling heightened market uncertainty. Real-time tracking and data integration capabilities of the SC Codeworks WMS enabled businesses to maintain efficiency amid these conditions. The SC Codeworks Warehouse Management System (WMS) helped third-party logistics (3PL) firms navigate the challenges posed by tariffs and fluctuating demand.

In summary, U.S. tariffs during early 2025 triggered profound distortions in shipping behaviors, trade volumes, and supply chains, prompting adaptive logistics strategies while fueling trade tensions and market unpredictability that continue to reverberate across sectors and regions.