Boosting the Productivity of Automotive Manufacturing with Metal Stamping Components

In the fast-paced world of automotive manufacturing, partnering with a reliable metal stamping parts manufacturer offers numerous advantages that enhance product quality, production efficiency, and overall project success.

High Precision and Consistent Quality

Reliable manufacturers utilize advanced tooling, precision stamping dies, and quality assurance equipment to ensure parts meet stringent automotive standards for fit, form, and function. The use of coordinate measuring machines and hardness testers guarantees the highest levels of precision and quality.

Cost-Effectiveness and Reduced Errors

Experienced manufacturers optimize tooling and processes to reduce material waste, production errors, and rework, translating into lower overall costs and higher efficiency. The "one-stop-shop" approach, where partners provide not only stamping but also secondary processes like tapping, riveting, welding, machining, and sub-assembly, simplifies logistics and shortens lead times.

Comprehensive Capabilities and Streamlined Supply

Many reputable metal stamping partners offer a wide range of capabilities, providing a seamless supply chain for B2B buyers. This results in reduced lead times, lower inventory costs, and better responsiveness to changes in production schedules.

Engineering Support and Early Design Collaboration

Partnering early with a stamping manufacturer can help redesign parts to optimize for metal stamping processes, which reduces development cycles and improves manufacturability. Collaboration with automotive design engineers can define part functional parameters, ensuring parts meet the specific safety, durability, and performance demands of the automotive industry.

Scalability and Flexibility

Reliable suppliers can handle both low and high-volume production runs using diverse press sizes and progressive stamping dies. They can adjust to the project scale and complexity, making them an ideal choice for the fast-paced automotive market.

Faster Turnaround Times

With advanced equipment and experienced engineering teams, dependable manufacturers deliver parts on schedule, even for complex or customized projects. This expedited delivery time is crucial in the competitive automotive industry.

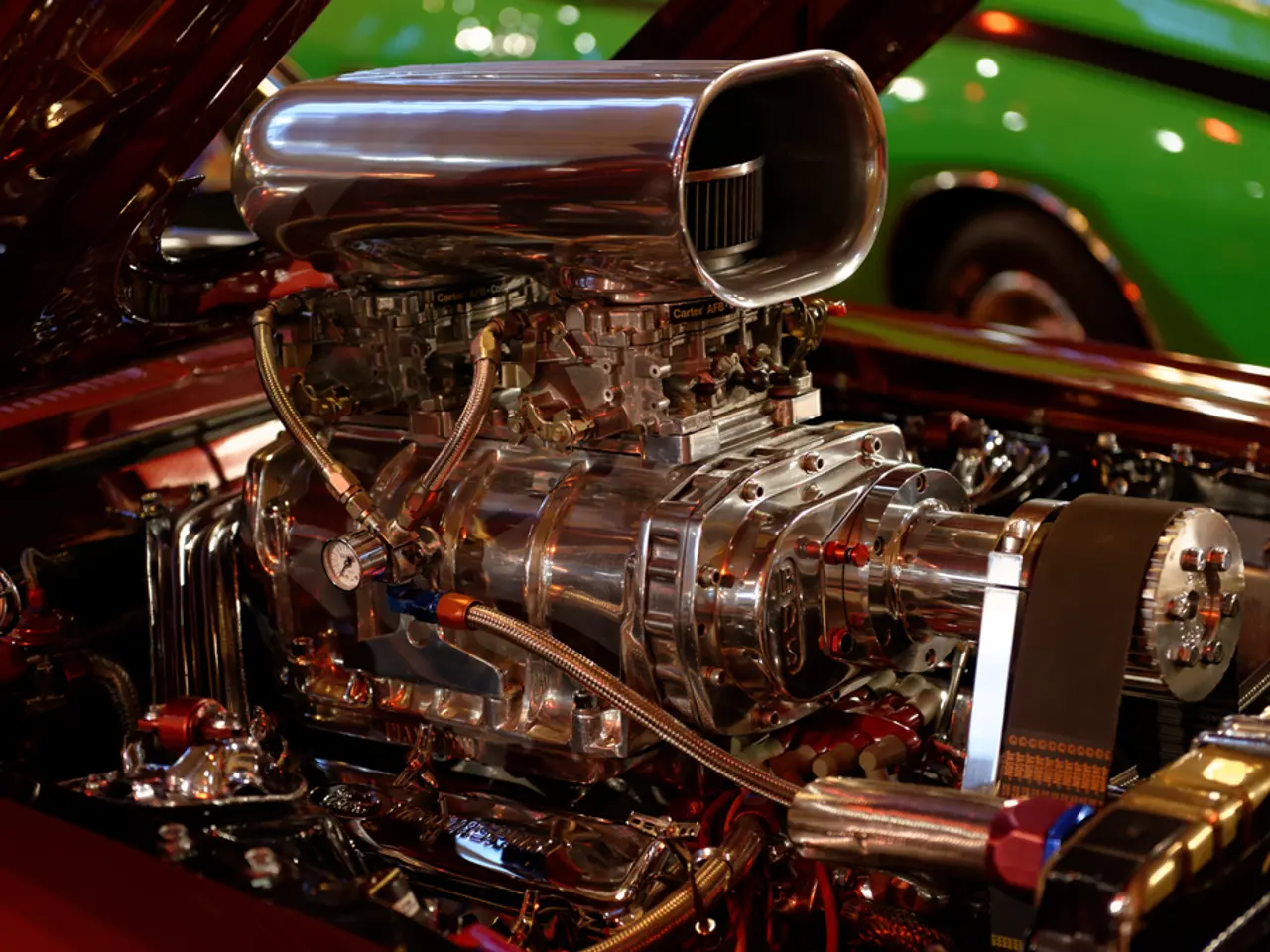

Improved Production Speed, Part Quality, and Durability

The use of advanced high-strength steel and aluminum in metal stamping improves production speed, part quality, and durability. The technology transforms flat metal sheets into specific shapes with precision at high speed, used for various automotive parts like chassis, body panels, brackets, and engine mounts.

Consistency in Part Dimensions

Consistency in part dimensions from metal stamping ensures a smoother fit during final vehicle assembly, reducing rework and minimizing quality issues. The precision of metal stamping technology is crucial for both structural and cosmetic parts in the automotive industry due to the need for perfect surface finishing.

In conclusion, collaborating with a reliable metal stamping manufacturer in automotive production ensures high-quality, cost-effective parts delivered efficiently. This partnership is supported by expert engineering and robust process controls tailored to automotive industry standards, leading to improved production speed, part quality, and durability.

The collaboration with a metal stamping manufacturer in the automotive industry not only guarantees high levels of precision and quality, but also offers cost-effectiveness due to reduced errors, material waste, and production rework.

A metal stamping partner's comprehensive capabilities and streamlined supply chain contribute to reduced lead times, lower inventory costs, and better responsiveness to changes in production schedules.